|

Pouch Processing Machine

Price 22500000 INR/ Unit

Pouch Processing Machine Specification

- Type

- Other

- Material

- MS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220-240 Volt (v)

- Warranty

- 1 Year

Pouch Processing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C), Cash in Advance (CID)

- Delivery Time

- 12-16 Week

- Main Domestic Market

- All India

About Pouch Processing Machine

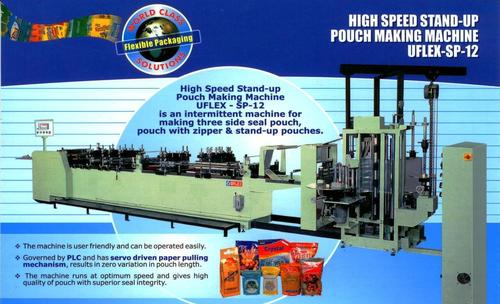

We take privilege to introduce ourselves as one of the primary and the excellent manufacturer and exporter of the Pouch Processing Machine These processing machines are extensively used for making pouches of various sizes in order to cater the diverse packaging needs of the clients Easy usage reliable results and market leading prices make our Pouch Processing Machine high in demand in the market

Features

Capable of making stand up three side seal pouches

Low power consumption

Touch screen

MODEL 3D 10

We also manufacture Pouch Processing System as per the specific requirements of our customers

Operational Speed

3 Side Gusset 30 35 Shots minute Two up operations up to pouch height of 245 mm possible Machine is capable of making Stand Up Three Side Seal Pouches also

Film Width

For Main Unwind 300 1000 mm

For Bottom Gusset 70 175 mm

For Side Gusset RW 140 350 mm

Max Film Roll Diameter

For Main Unwind 600 mm

For Bottom Gusset 450 mm

For Side Gusset 500 mm

POUCH SIZE RANGE

Pouch Width 80 400 mm

Upto 360mm without skipping

Pouch Height 140 495 mm

Side Gusset 60 165 mm

Side Gusset Registered Pouch

3 Side Gusset on 2Up basis max height 245mm

Min Laminate Structure 12 Pet12 Met Pet50 Poly

Preferred 19 Pet45 Poly

Extra Waste Laminate 1010mm Top Bottom Side Gusset

Electrical Supply 3 Phase 415 Volts AC 10 50 Hz

Electrical Power Consumption 55 KW Max

Product Counter Voluntary Setting Counter

Prime Movers Main Motor 3 Phase 415Volts AC 50Hz 10HP Star Connection

Unwind Motor 3Phase 415V AC50Hz 1HP Delta Connection

Temperature Control PID Controlled Variation

MMI Touch Screen Coloured Monitor 6 12

Painting Plain Colour Standard Colour Steel Grey Customers colour preference is acceptable

Air Consumption 100 Cubic Mtr Hr Pressure 6 Bar Water Contents 001

Water Consumption 8 to 15 Ltr Min Pressure 1 to 2 Bar at machine Temperature 5 to 10C

Dimensions

Length 14 Meter

Width 4 Meter

Height 3 Meter

WEIGHT 6200 Kgs Approx

Optional Attachment

Uflex Design Slider Attachment Patented

Zipper AttachmentSystem suitable to Uflex Zipper Slider with or without Uflex design diaphram Patented

Section 2 Composition Of Machine

The following is a comprehensive list of major items of supply

Main Machine Unit The Main Machine Unit further consists of the following

Cutting Unit This is the final operating unit driven by Pneumatic Cylinder

Front Cooling Station The final station for cooling provided by means of press type cooling arrangement driven by Rocker Arm for the sealing perpendicular to the flow of film

Front Sealing Station The final station provided by means of press type sealing arrangement driven by Rocker Arm for the sealing perpendicular to the flow of film

Photo Cell Datalogic Station The NT 6 series photo cell installed for the feedback of Registration mark on the film

Bit Sealing Station This station provides the 100 mm max Bit Sealing at the edge of the film

VNotching Station This makes V shape Notch on the pouch for the tearing

Pneumatic Punching Station This station provides a wide range of punching on the pouch for the stand up pouch bottom sealing carry bag punching purpose

Rear Cooling Station The parallel cooling station with respect to the flow of film providing a high class sealing finish to the rear sealing station

Rear Sealing Station Radius Sealing The parallel sealing station with respect to the flow of film provided for the radius sealing of the film

Main Drive Assembly This assembly constitutes a camfollower mechanism which give drive to Rocker Arm assembly for the reciprocating motion of the stations

Miscellaneous Assemblies

Slitting Assembly This unit is oriented before the cutting unit which provides the parallel cutting on the film flow for the multiple production per stroke

Pinch Roller Assembly This unit oriented after horizontal dancing assembly which directs the web flow of upper lower layer of film

Lubrication Network With the help of oil pump this network lubricated all the Cam follower in the main drive

Horizontal Dancing Unit This unit provides constant tension and feed to the upper and lower film

Unwind Unit This is the third unit of the machine placed behind the horizontal dancing unit

The above unit is vertical unwind incorporated with a Lever Arm Dancing Roller Assembly and to side unwind units for the bottom film

Section 3 Descriptive Machine Specifications

Main Machine Unit

Cutting Unit This is the last and the final operating unit which cut down the plastic film after it had been sealed and cooled thoroughly from the centre and side thereby leaving one of the opening for filling This assembly constitutes two blades adjusted at an angle Blade 1 and 2 having a scissors cutting operation

Front Cooling Station This station is provided by means of press type cooling arrangement for a proper and smooth surface finish of the side sealing which has just been done by means of the side sealing units This front cooling station is fixed with a upper station which is mounted by the spring on the top and nuts on the lower position of upper station The pressure of the cooling unit can be adjusted according to the type of plastic film and sealing temperature by means of this spring and the position can be adjusted by means of the nuts This cooling station can be moved to and for by means of rack and pinion arrangement The cooling water required is about 8 L 15 L max coming from the chilling plant

Front Sealing Station This station is divided into the front sealing station No 1 Heater No1 and the front sealing station No2 Heater No2 The front sealing station having a sealer on the lower side which seal the plastic film from the lower portion This sealer can be changed according to the sealing width as accordingly demanded The sealing station No2 having a sealer from the upper portion seals the film from the upward sides The position and movement of the station can be accordingly done as discussed above The next main unit of this machine is the unwind unit of this machine is the unwind unit which unwinds the laminated sheets in the roller form

Photocell Station This station is placed just behind the front pull roller This constituted a photocell which serves out the colour combination and directs the accurate cutting at a very high speed The photocell is made to sense a colour mark on the film

Bit Sealing Station This assembly oriented before the front sealing assembly constitutes of bit sealer used in part sealing at the edge of the film while stand up pouches The common size of the Bit sealer are LxW 10x80 10x100 12x80 12x100 14x80 14x100 15x80 15x100 etc

V Notching Station This station performs the operation of Notching mark on the pouch which requires for tear up the filled pouch This station incorporated of a pneumatic actuator which reciprocates the hardened notching tool thru the film thickness The maximum frequency of this unit is 100 stroke Min

Pneumatic Punching Unit This station incorporate of a punch and die set driven by a pneumatic actuator which makes the punches on the film The punching on the centre seal pouch is required for the carrying purpose The die punch set has a touch of Uflexibility in various shape sizes ie round square oval UFO shape etc

Rear Cooling Station These cooling station has got the same function as the front cooling station do for the side sealing but they are incorporated for the centre sealing which has just been done by the rear sealing station The setting of pressure and adjustment of the stations can be done as discussed above

Rear Sealing Station Radius Sealing The rear sealing station is the main unit which starts sealing the laminated film parallel to the flow by sealing radially The radius sealing is responsible for the stand up pouch semi stand up pouch and the zipper sealing on the upper lower layer of the film This is one of the main sealing station on the machine The station has 4 pair of sealing set which compressed on each other by the Rocker Arm drive in between which both the layer of the film flows

Main Drive Assembly This assembly constitutes the Camfollower mechanism linked by a sprocket chain drive which is further driven by 5 HP III phase induction motor with a warm reducer of ratio 130

The Camfollower assembly further gives drive to the Rocker Arm assembly which directs the reciprocating motion of all the stations

Miscellaneous Assemblies

Slitting Assembly The slitting assembly is oriented before the cutting unit which provides the parallel tearing of the film by means of Razor blades on the flow of film These assembly is used for the multiple pouch production per shot

Pinch Roller Assembly This assembly is oriented after the horizontal dancing unit and constitutes of 2 parallel rubber roller with a fixed gap in between them The pinch roller controls the web of both the layer of film flow

Lubrication Network This is an oil pipe line network which is initially connected to the piston pump of 10 CCstroke which provides the lubrication to the all Cam follower assemblies

Optional Assemblies

Scrap Winding Machine This machine is used for the winding of side web which is parted by the slitting unit from the main film This machine is driven by a 12 HP induction motor and can be placed anywhere near the main machine

Gusset Folding Assembly This is a new concept in the pouch manufacturing industries by which we developed a bottom folded gusset pouch These pouches can intake a greater amount of filler with respect to the conventional threeside seal pouch The gusset assembly is incorporated by the two circular angular discs on the one side of the film which is in the single layer The position of the gusset disc can be adjusted in X Y axis by means of the knobs provided on the mountings

DPunch Attachment Assembly This is a separate unit which can be mounted on the main machine This unit is controlled by a separate PLC and all the motions are pneumatically generated Various nos of Pneumatic actuators and vacuum generators are used in this unit

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pouch Making Machines Category

Flat Bottom Pouch Making Machine

Price 12500000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Control System : Human Machine Interface

Computerized : No

Drive Type : Electric

Automatic Flat Bottom 3D-12 Pouch Making Machine

Price 22500000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Control System : PLC Control

Computerized : No

Drive Type : Electric

Pouch Making Machines

Price 10000000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Control System : PLC Control

Computerized : Yes

Drive Type : Electric

Automatic Pouch Making Machine

Price 15000000 INR

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Control System : PLC Control

Computerized : Yes

Drive Type : Electric

|

UFLEX LIMITED (ENGINEERING DIVISION)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry