|

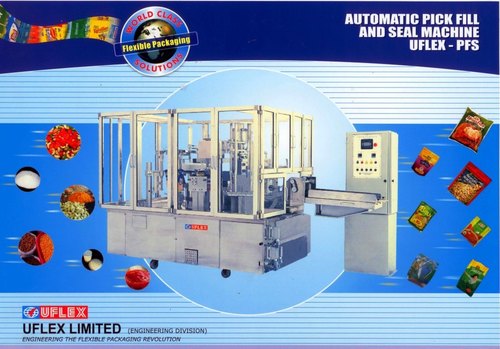

Automatic Pick Fill Seal Machine

Price 4500000 INR/ Piece

Automatic Pick Fill Seal Machine Specification

- Product Type

- Automatic Pick Fill Seal Machine

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Processing Type

- Pouch Packaging

- Voltage

- 220/380 V

- Dimension (L*W*H)

- 1800 x 1300 x 1500 mm

- Weight

- 800 kg approx

- Color

- Silver

Automatic Pick Fill Seal Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- 12-16 Week

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Asia

- Main Domestic Market

- All India

About Automatic Pick Fill Seal Machine

We have gained immense recognition in the worldwide market for aesthetically manufacturing and exporting a wide range of Automatic Pick Fill Seal Machine. Available with various dozing system for different products like liquid and paste, this machine is an advance mechanical robotic system that ensures no pick - no fill and no fill - no seal operations. Our Automatic Pick Fill Seal Machine is extensively used for packing powder, granules, liquids and paste in preformed pouches.

Features:

- Simple change over operation sequence

- Automatic in-feed conveyor system

- Accuracy

Further Details

(MODEL: UFLEX-PFS)

Pick fill seal machine is a fully automatic, 10 station rotary indexing filling, intermittent motion and sealing machine to pack liquids, powder, granules and paste in preformed pouches like center seal pouch, three side seal pouch, stand-up pouch and zipper pouch etc. made-up of heat sealable laminated film. Automatic pick fill seal machine can be provided with the various dozing system for the products like liquid and paste. The machine is a state-of-the-art mechanical robotic system, which has a close loop smart control system, which ensures the operation:

NO PICK - NO FILL

&

NO FILL - NO SEAL

The above close loop system ensures practically negligible wastage of packing material and the product. The machine is an operator friendly machine and has a very simple change over operation sequence from one pouch size to another. The machine has an automatic in-feed conveyor system for preformed pouches and an out-feed dispensing ramp for the filled and sealed out-going pouches.

Pick Fill Seal Machine

| 1. Product to be packed |

- Liquid : Oil, MineralWater, Ketchup,Syrup, Etc. - Powder : Milk Powder, Heena, Various Flour Etc. - Granules : Tea, Peanuts,Cashew Nuts, Rice, Pulses Etc. - Others : Light Weight Hardware, Pickle Etc. |

||||||||||||

| 2. Qty. to be packed |

- 5 gms to 1000 gms. (Depending upon product to be packed) |

||||||||||||

| 3. Machine |

- Automatic Pick Fill & Seal Machine ( MODEL : FLEX - PFS ) |

||||||||||||

| 4. Control |

- PLC ( Programmable Logic Control ) |

||||||||||||

| 5. Temperature Controller |

- PID type |

||||||||||||

| 6. Pouch type |

- Preformed |

||||||||||||

| 7. Pouch Size |

|

||||||||||||

| 8. Filling system |

- Cup Filler, Auger Filler, Gravity Matrix, Load Cell Weigher |

||||||||||||

| 9. Speed |

- 40-45 Pouches/min. (Depending upon product to be packed) |

||||||||||||

| 10. Accuracy |

+ 2 % Output & Accuracy depends on following:

|

||||||||||||

| 11. Power Consumption |

- 5 KW |

||||||||||||

| 12. Power supply |

- 415 V/A.C/ Three Phase |

||||||||||||

| 13. Utility |

- Compressor : 30 CFM, 10 Bar |

||||||||||||

| 14. Feature |

- Easy Change over to Various Pouch Size - Sensor to Avoid Product & Pouch Wastage |

||||||||||||

| 15. Optional Feature |

- Coding - Dust Extraction System (at an extra cost ) |

||||||||||||

| 16. Dimensions |

L=3600 mm., W= 2800 mm., H = 1900 mm. |

||||||||||||

| 17. Weight |

1210 Kg. ( Approx.) |

||||||||||||

Advanced Pouch Packaging Technology

This machine utilizes a PLC-based computerized control system to automate the entire pick, fill, and seal process. The stainless steel construction not only ensures durability but meets stringent hygiene standards, making it suitable for food, pharmaceutical, or other product packaging. Its automatic operation reduces manual labor and increases productivity while maintaining consistent quality across batches.

Designed for Exporters, Manufacturers & Suppliers

Exporters, manufacturers, and suppliers across India benefit from this high-performance automatic packaging solution. Its adaptable design allows integration into existing production lines, guaranteeing smooth operation and efficient space utilization. With reliable engineering and easy maintenance, this machine provides a long-term turnkey solution for demanding packaging requirements.

FAQs of Automatic Pick Fill Seal Machine:

Q: How does the Automatic Pick Fill Seal Machine operate?

A: The machine runs on a PLC-based computerized control system, automatically picking, filling, and sealing pouches. This ensures accurate and efficient packaging with minimal manual intervention.Q: What materials and products can this machine package?

A: It is suitable for packing a variety of products including food, pharmaceuticals, and other goods, using pouches, thanks to its hygienic stainless steel build and adaptable processing type.Q: When is installation and commissioning performed for buyers in India?

A: Professional installation and commissioning are typically provided upon purchase, with scheduling coordinated to align with buyers requirements across India.Q: Where can the Automatic Pick Fill Seal Machine be used?

A: This machine is ideal for use in industrial settings such as food processing, pharmaceutical manufacturing, and other industries where reliable pouch packaging is essential.Q: What is the main process involved in pouch packaging using this machine?

A: The primary process involves automatically picking empty pouches, filling them with the desired product, and then sealing them securely, all managed by the advanced PLC-based system.Q: How does usage of this machine benefit manufacturers and exporters?

A: Manufacturers and exporters benefit from its high speed, consistent packaging quality, low labor dependency, and compliance with hygiene standards, leading to better productivity and reduced operational costs.Q: What are the dimensions and weight of the machine?

A: The machine measures 1800 x 1300 x 1500 mm and weighs approximately 800 kg, making it suitable for installation in standard industrial spaces.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Purpose Machines Category

Pick Fill Seal Machine

Price 4500000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, PLC Based Touch Screen Panel

Voltage : 220380 V

Automatic Grade : Automatic

Product Type : Pick Fill Seal Machine

Vacuum Brick Pack Form Fill Machines

Price 3500000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, PLC Based Control Panel

Voltage : 220 V / 380 V, 50 Hz

Automatic Grade : Automatic

Product Type : Vacuum Brick Pack Form Fill Machine

Special Purpose Vacuum Brick Pack

Price 7500000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Voltage : 415 V/A.C./ Three Phase / 50 Hz Volt (v)

Automatic Grade : Automatic

Product Type : SPECIAL PURPOSE MACHINES

|

UFLEX LIMITED (ENGINEERING DIVISION)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry