|

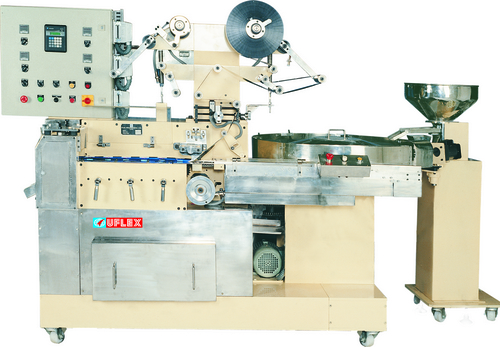

Automatic Horizontal Flow Wrap Machine

Price 3500000 INR/ Piece

Automatic Horizontal Flow Wrap Machine Specification

- Power Supply

- AC

- Features

- Robust Structure, Touch Screen Panel, Error Alarm System

- Usage

- Wrapping of Biscuits, Confectionery, Soaps, and similar products

- Application

- Food, Pharmaceutical, Cosmetics, Stationery Packing

- Noise Level

- Low

- Filling Range

- Adjustable (as per product size)

- Type

- Automatic Horizontal Flow Wrap Machine

- Material

- Stainless Steel

- Auxiliary Packaging Machine Type

- Wrapping Machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 2.5 kW

- Weight (kg)

- 550 kg

- Dimension (L*W*H)

- 4000 mm x 1100 mm x 1550 mm

- Color

- Silver / Customized

- Sealing Type

- Center Seal

Automatic Horizontal Flow Wrap Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 12-16 Week

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Automatic Horizontal Flow Wrap Machine

Being among the topnotch organizations, we are involved in manufacturing and exporting a sturdily constructed array of Automatic Horizontal Flow Wrap Machine in the worldwide market. Our range is designed and developed in accordance with the global quality standards. This versatile Automatic Horizontal Flow Wrap Machine is ideally used for wrapping cubical, irregular shaped solid products and cylindrical products such as disposable syringe, bottle, soap, cake and pre-filled pouches.

Key Attributes:

- Programmable logic control

- Operator friendly man machine interface

- Minimum wastage of packing material

Further Details :

Horizontal Flow Wrap Machine is a very versatile machine which can wrap cubical, irregular shaped solid products, cylindrical products like Bottle / Soap / Cake /Bearing/ Disposable syringe / Pencil Cells / Ice Cream / Spark Plug /Piston Rings/ pre-filled pouches and Similar Product in pillow pack pouch.The machine is an operator friendly with a speed range of 25 to 125 packs per minute. The machine is controlled by programmable logic control and provided with an operator friendly MMI (man machine interface).

All the temperature controllers provided in the machine are PID. The machine has a built in high response photo registration,cutting of the film even at high speeds which results in minimum wastage of packing material and high sensitivity to ensure accurate positioning of the product .The machine comes with latest and unique features like pouch length adjustment mechanism for a wide range of roll width, adjustable forming unit, , which ensure short change over times as well as no change parts.

The machine can be provided with customized in-feed system in synchronization with the process of manufacturing . This machine can be used to pack the products like disposable syringes,soap, chocolate bars, IV Fluid bottles, auto spare parts, bearing etc.Machine can be provided with an optional attachment like overload clutch, coding unit etc. (at an extra cost).

Features of Horizontal Flow Wrap Machine:

| Product to be packed | Pharmaceutical / Bakery / Personal Care/ Stationary / Automobile / Electrical & other Products |

| Qty. to be packed | Single (can be designed according to the requirements) |

| Machine |

Automatic Flow Wrap Machine (MODEL : UFLEX FW - 1001) |

| Feeding system | Auto Feeder / Manual |

| Control | PLC (Programmable Logic Control) |

| Temperature Controller | PID type |

| Pouch type | Centre Seal Pillow type |

| Pouch Size |

|

| Speed | 25 - 125 Pouches / Min. Output depends on (Dimensions & Shape of product Characteristics of packaging material) |

| Power Consumption | 5 KW |

| Power supply | 220 V / AC / Single Phase / 50 Hz |

| Optional Feature | Coding Device Batch Cutting Over Load Clutch |

| Maximum Roll width | 380 mm |

| Dimensions |

L = 4200 mm., W = 1500 mm., H = 1700 mm. |

| Net Weight | 850 Kg. (Approx.) |

Advanced Modular Structure for Durability

The machines robust, modular stainless steel framework not only ensures long-term reliability but also allows for flexible maintenance and upgrades. This construction is ideal for demanding industrial settings where consistent performance is essential, minimizing downtime and supporting increased productivity.

User-Friendly Operation with Enhanced Safety

A touch screen interface paired with PLC control streamlines setup and monitoring. Swift emergency stop capability, comprehensive safety guards, and an automatic lubrication system safeguard operators while prolonging the life of critical components. The inclusion of a photoelectric sensor further enhances operational safety and precision.

Versatile Application Across Multiple Industries

Engineered for versatility, this flow wrap machine is suitable for food, pharmaceutical, cosmetic, and stationery product packaging. Its adjustable filling range and customizable settings enable precise handling of various product sizes, making it an excellent fit for manufacturers and suppliers across diverse markets.

FAQs of Automatic Horizontal Flow Wrap Machine:

Q: How does the automatic horizontal flow wrap machine detect and align products during packaging?

A: The machine is equipped with a photoelectric sensor that accurately detects and aligns products as they move along the conveyor. This ensures consistent positioning for precise wrapping and minimizes errors during fast-paced industrial operation.Q: What are the main benefits of the modular design in this packaging machine?

A: The modular design allows for easier maintenance, quick component replacement, and future upgrades. This approach increases the machines service life, simplifies troubleshooting, and provides flexibility in adapting to evolving production requirements.Q: Where is this flow wrap machine best suited for installation and use?

A: It is designed exclusively for indoor industrial environments, such as food processing plants, pharmaceutical factories, cosmetics production lines, or stationery packaging facilities. Its robust structure and safety features ensure optimal operation in controlled, professional settings.Q: When should the automatic lubrication system be checked or maintained?

A: Although the lubrication system functions automatically to protect key moving parts and reduce wear, it is recommended to inspect it periodically according to the manufacturers maintenance schedule to ensure optimal performance and longevity.Q: What types of products can be efficiently wrapped with this machine?

A: This machine is adept at packaging a variety of items including biscuits, confectionery, soaps, and other similarly sized goods within its height and filling range. The adjustable settings accommodate different shapes and sizes across multiple industries.Q: How does the machines user-friendly interface improve operation processes?

A: The integrated touch screen panel provides an intuitive interface for operators, allowing straightforward adjustment of parameters, fast error identification via the alarm system, and smooth management of packaging tasks, enhancing workflow efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wrapping Machines Category

High Speed Candy Wrapping Machine

Price 1500000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Weight (kg) : 1200 kg

Power : 2.5 kW

Dimension (L*W*H) : 4000*900*1500 mm

Flow Wrapping Machine

Price 1500000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Weight (kg) : 850 Kg. (Approx.) Kilograms (kg)

Power : 5 Kw Watt (w)

Dimension (L*W*H) : L=4200 mm., W= 1500 mm., H = 1700 mm. Millimeter (mm)

|

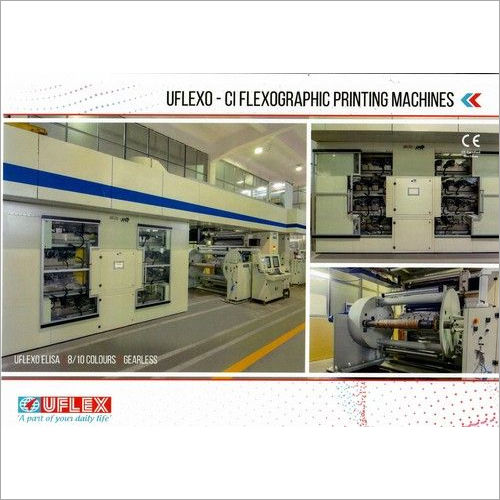

UFLEX LIMITED (ENGINEERING DIVISION)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry