|

Inspection Rewinding Machine

Price 4000000 INR/ Piece

Inspection Rewinding Machine Specification

- Power

- 3 HP

- Usage

- Label, Film, Paper, Foil Roll Inspection

- Function

- Inspection and Rewinding

- Accuracy

- 0.5 mm

- Operating Mode

- Continuous

- Control Mode

- Automatic/Manual

- Standard

- ISO 9001:2015

Inspection Rewinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Main Export Market(s)

- South America, Western Europe, Eastern Europe, Middle East, Central America, Africa, Australia, Asia, North America

- Main Domestic Market

- All India

About Inspection Rewinding Machine

Backed by our rich industrial experience, we are actively engaged in offering a wide assortment of quality assured Inspection Rewinding Machine to our valuable customers. These machines are manufactured with the aid of advanced machinery techniques as per the set industry standards. These machines are further tested on various parameters by our quality controllers to ensure flawlessness and best quality. Our offered Inspection Rewinding Machine is widely demanded among the clients for its optimum performance and high efficiency.

Features:

- Simple installation

- Easy to operate

- Negligible maintenance

Superior Inspection and Rewinding Performance

This machine streamlines quality control by enabling thorough inspection and rewinding of multiple material typespaper, film, labels, and foil. Its high-precision accuracy and adjustable speed settings ensure that each operation meets stringent standards, reducing wastage and improving output reliability for manufacturers and exporters.

Advanced Tension and Safety Systems

The automatic pneumatic brake maintains consistent material tension, guaranteeing smooth winding and unwinding at all working speeds. Integrated safety mechanisms, such as the emergency stop and protective safety guard, uphold operator safety and comply with international ISO 9001:2015 standards.

User-Friendly Digital Controls and Display

Operators benefit from a digital meter for precise length counting and selectable automatic or manual control modes, allowing for tailored workflow management. The illuminated inspection table improves defect detection efficiency, ensuring products are consistently inspected to high standards before further processing or dispatch.

FAQs of Inspection Rewinding Machine:

Q: How does the inspection rewinding machine operate for different material types?

A: The machine is compatible with paper, film, foil, and labels. It offers variable speed control (10-200 m/min), an illuminated inspection area, and automatic tension adjustment to ensure consistent rewinding and precise defect inspection across different materials.Q: What benefits does the automatic pneumatic brake system provide?

A: The automatic pneumatic brake maintains uniform tension during operation, preventing roll deformation and material damage. This results in smoother rewinding, reduced wastage, and improved final product quality.Q: When is it advisable to use the inspection rewinding machine in the production process?

A: It is typically used after initial printing or converting processes to inspect, correct, and rewind rolls before packaging or further processing, ensuring only quality-compliant material proceeds to the next production stage.Q: Where can this machine be installed and what are its space requirements?

A: With dimensions of L 2200 x W 1700 x H 1400 mm and a weight of approximately 900 kg, the machine is suitable for installation in production lines or dedicated quality control areas within label, paper, or film manufacturing facilities.Q: What is the inspection process like on this machine?

A: Operators feed the roll onto the machine, set the desired speed and tension, and use the illuminated table with a slit lamp to visually inspect for defects as the material is rewound. Any defects can be marked or corrected in real time.Q: What are the key safety features incorporated in this machine?

A: The machine includes an emergency stop button and a safety guard to protect operators during use, in compliance with stringent ISO 9001:2015 safety standards.Q: How does using this machine improve overall production efficiency?

A: By combining inspection and rewinding in one step with high accuracy (0.5 mm), the machine streamlines quality assurance, minimizes downtime, and ensures that every roll meets quality requirements before shipment or further conversion.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inspection Machine Category

Rewinding Inspection Machine

Price 50000000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : PLC Controlled Panel with Touchscreen HMI

Power : Other, 2 HP (1.5 kW), 3 Phase, 415V

Standard : ISI Marked Components, Complies with Industrial Machinery Standards

Function : Inspection and Rewinding of Film, Foil, Paper, and Flexible Packaging Materials

Inspection Machine Rir

Price 1500000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Automatic

Power : Other, 220V AC, 50/60Hz

Standard : Industrial Grade

Function : Visual and dimensional inspection

Super DDRSL Slitting Machine

Price 3600000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Automatic

Power : Other, 7.5 kW

Standard : Industrial Grade

Function : Slitting and Rewinding of Roll Materials

Inspection Machine Hsr

Price 1500000 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Automatic

Power : Other, 220V / 50Hz

Standard : CE Certified

Function : Visual inspection and defect detection

|

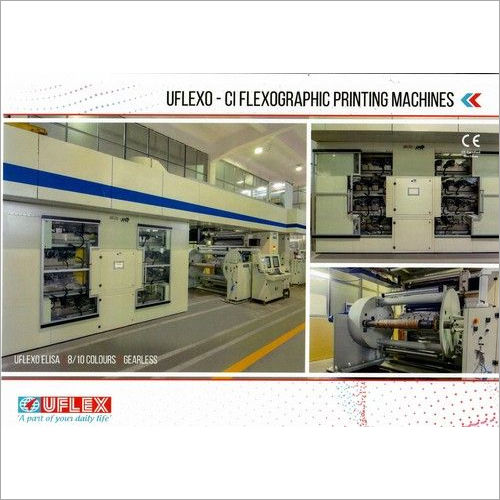

UFLEX LIMITED (ENGINEERING DIVISION)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry