|

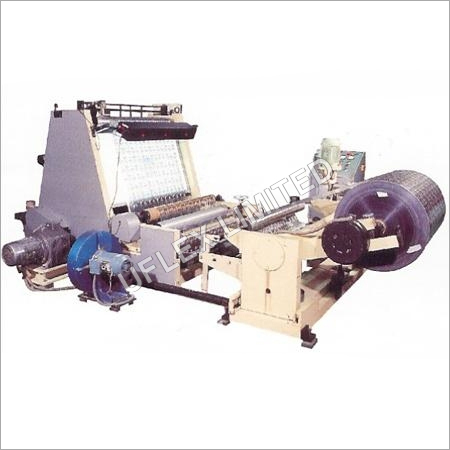

Inspection Rewinder Machine

Price 4000000 INR/ Piece

Inspection Rewinder Machine Specification

- Power

- 3 kW

- Usage

- Quality Checking and Rewinding of Flexible Packaging Materials

- Function

- Visual Inspection and Rewinding of Films

- Accuracy

- 0.02 mm

- Operating Mode

- Automatic

- Control Mode

- PLC Controlled

- Standard

- ISO 9001:2015

Inspection Rewinder Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Main Export Market(s)

- Western Europe, Australia, Central America, North America, South America, Eastern Europe, Africa, Middle East, Asia

- Main Domestic Market

- All India

About Inspection Rewinder Machine

Counted as the dynamic organization and a key player in the global packaging industry, we are manufacturing and exporting a highly advanced range of Packaging Inspection Machine. These inspection machines are widely used to rewind printed, unprinted and substrate that has to be processed further invariably. Offered in various technical specifications, our respected patrons can avail this Packaging Inspection Machine from us at cost effective prices.

Features

- Eco friendly nature

- Low power consumption

- Enhanced functional life

General Description:

We are offering Packaging inspection machine (MODEL RIR - 1000). This equipment has been specially designed to rewind printed / unprinted, substrate which has to be processed further invariably this further processing means "value addition" and therefore it is imperative that the printed /unprinted substrate should be subjected to through inspection and rejections, if any due to misregistration / pinholes, while printing / metallizing are removed prior to value addition.

The machine configuration has been depicted in the enclosed drawing and as obvious it essentially consists of:-

a) Floating Unwind Stand. (Half Turret)

b) Main Machine

1. Floating Unwind

The unit consists of a precision machined base, on which are located hardened and ground bearing tracks. The floating platform fitted with four number of bearing can freely oscillate in the machine base. Two side frames are fixed on the floating platform.

2. Half Turret

A pivot shaft is mounted on bearing locks on top of side frames. An edge guide unit is provided to position the unwind stand as per the reel telescopy. Cast Iron fully machined rewind arms are accurately aligned and permanently fixed to the center pivot shaft, which acts as a fulcrum for unwind arm. A drive train from Powder Brake is housed on the drive side arm.

Main Machine

The Packaging inspection equipment consists of a fully machined cast iron side frame within which are located suitable number of web support rollers, the web viewing light source box and the rewind station. Operator's/Inspector's convenience has been kept in mind while designing the web viewing area.While the operators sits in front of the machine (close to floating unwind stand) the web travels upwards on an incline and the printed matter can be viewed without any strain. Diffused lighting is provided behind the incline in case transparent web is to be inspected.

The rewind shaft is powered through a gear train from a constant torque characteristics variable speed drive. The rewind tension can be controlled by adjusting the braking torque, controls for which are centrally located.

Packaging inspection equipment Specifications:

| Maximum Parent reel Width | 1020 mm |

| Maximum Parent Reel Dia | 800 mm |

| Maximum Rewind Reel Dia | 800 mm |

| Maximum Design Speed | 120 M/min. |

| Drive | : 5 HP Eddy current variable speed drive with controls |

| Tension Device | 20 Kgm Powder Brake of Dynaspede make |

| Pneumo Hydraulic Edge Guide | Complete with power pack sensor and controls with 0.5 HP AC Motor. |

Versatile Material Handling

This machine accommodates a broad range of material widthsanywhere between 300 mm and 1200 mmand supports various film types including BOPP, PET, PVC, and paper. Its robust construction makes it highly adaptable to the dynamic requirements of flexible packaging industries, guaranteeing reliable performance for diverse production needs.

Precision & Automation for Consistent Quality

With PLC control, automatic load cell-based tension regulation, and a servo-driven system, the inspection rewinder ensures consistent, accurate inspection and rewinding of films. The touchscreen HMI streamlines operation while the 0.02 mm accuracy supports precise quality assessments, reducing user intervention and operator fatigue.

Safety and Compliance Assured

Safety features such as emergency stop buttons and robust safety guards, coupled with compliance to ISO 9001:2015 standards, make this equipment a secure choice for demanding production environments. Its automatic operation and well-designed control system further enhance efficiency and operator safety.

FAQs of Inspection Rewinder Machine:

Q: How does the automated tension control system work in this inspection rewinder machine?

A: The machine utilizes an automatic load cell-based tension control system to maintain consistent film tension throughout the inspection and rewinding process. This ensures optimal film alignment and reduces the risk of film breakage or wrinkling, enhancing both quality and productivity.Q: What types of films and materials can be inspected and rewound using this machine?

A: This machine is specifically engineered to support films such as BOPP, PET, PVC, and paper, making it suitable for a wide variety of flexible packaging materials used in the food, pharmaceutical, and consumer goods industries.Q: When is it advisable to use this rewinder machine within the production process?

A: The inspection rewinder is ideally integrated after the printing or slitting stage in the packaging production line, providing an essential quality control checkpoint before products proceed to final packing or dispatch.Q: Where can this machine be installed and what are the space requirements?

A: Designed with compact dimensions of 2700 mm by 1200 mm by 1400 mm, the machine can be set up in standard production areas. Its robust build allows seamless installation in manufacturing facilities, conversion plants, or quality control stations.Q: What is the primary process flow for visual inspection and rewinding on this machine?

A: Material is loaded on the unwinder, passed over the inspection surface for visual checks, and then rewound onto a new core. Operators can monitor and manage inspection via the touchscreen HMI while automated functions handle tension and speed adjustments.Q: How does this machine benefit a flexible packaging manufacturer or exporter?

A: By combining efficient inspection and precision rewinding, the machine enhances product quality, reduces wastage, and automates quality assuranceimportant factors for manufacturers and exporters seeking to maintain high standards and customer satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

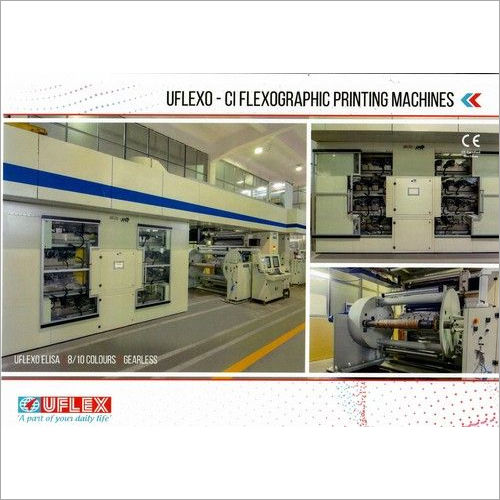

More Products in Inspection Machine Category

|

UFLEX LIMITED (ENGINEERING DIVISION)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry